Environmental Sustainability Solutions

Gurtler Industries offers a wide range of products and services that can help a laundry operation be more energy efficient, conserve resources, and have a lower impact on the environment. The following is a brief compilation of these products and programs.

PRODUCT TECHNOLOGY

New Surfactant Technology

Gurtler has a line of detergents available that utilize surfactant technology that meets the requirements of the US EPA’s Safer Detergent Stewardship Initiative (SDSI). These products incorporate surfactants that are considered more eco-friendly due to their improved biodegradability.

- Recommended Products: Gurtler’s gēLINE currently has over 10 products that meet the new EPA SDSI Standard.

Concentrated Product Technology

Gurtler’s liquid products have been formulated to maximum concentrations so a little product goes a long way. With high-active products we reduce the amount of packaging materials that are required and reduce delivery frequency (saving fuel and transport costs).

- Recommended Products: Work•Fast, Power Jolt (alkalis) and Work•Clean, gēBlast 2X Pro, Pulse Advance, or Power Forward (detergents).

Limited Phosphate Products

Gurtler has a full line of low and no-phosphate detergents and builders. Limiting the amount of phosphate that is discharged to the waste stream helps maintain the quality of our surface waters, streams and lakes.

- Recommended Products: Non-Phosphate – Work•Smart (conditioner), Pulse Ultra (alkali), all liquid detergents. Low Phosphate – NDT Endorse (detergent), Power Block (conditioner).

Low Temperature Products

Gurtler has a full line of products designed to work most efficiently at lower temperatures, conserving energy.

- Recommended Products: Work•Clean, Pulse Advance, Power Drive, Power Blast, Power Forward (detergents), Work•Smart, Power Block (conditioners).

Oxygen Bleaching Products

Gurtler has broad experience with the use of oxygen bleaching technology including peracetic acid technology. Chlorine bleach can have adverse effects on the environment as it is discharged into the waste stream. The use of oxygen bleaching is a practical alternative to chlorine.

- Recommended Products: NDT Oxy-Bleach Plus, PerAction, Oxcellerate.

Enzyme Technology Product

Gurtler has enzyme-based detergents that may, in many cases, significantly reduce or eliminate the need for bleaches for stain removal.

- Recommended Product: gēClean.

Our gēLINE employs several progressive technologies to further energy efficiency and resource conservation. Please review our gēLINE page for comprehensive information on our innovative product.

SERVICE

Wash Formula Design

Gurtler works with each customer to design optimized wash formulas that balances productivity, chemical levels, water requirements, and energy usage with overall quality. The design of overall wash formulas for an operation is a science that requires consideration of numerous factors. When energy and resource conservation has a high level of criticality, our Gurtler Experts can set up your wash formulas to be most efficient.

Equipment Audits

Gurtler’s Technical Service team performs routine equipment audits in the laundry to make sure that critical components are functioning as needed. For example, our technicians check the water levels and drains for proper function to make sure that water is not wasted. Wash times and temperatures are also routinely checked to make sure that the operation is running efficiently and utilizing the appropriate level of hot water and energy.

ENERGY CONSERVATION

Energy Audits

Gurtler service technicians will perform a thorough energy audit that evaluates the amount of energy used in the overall washing process. This audit can be used to evaluate potential energy savings opportunities with use of lower temperature wash technology.

Dryer energy issues: Gurtler evaluates the entire energy profile in the laundering process, including the drying operation which is the number one energy requirement. Evaluation of extraction efficacy will help pinpoint potential savings opportunities.

WATER CONSERVATION

Water Reuse

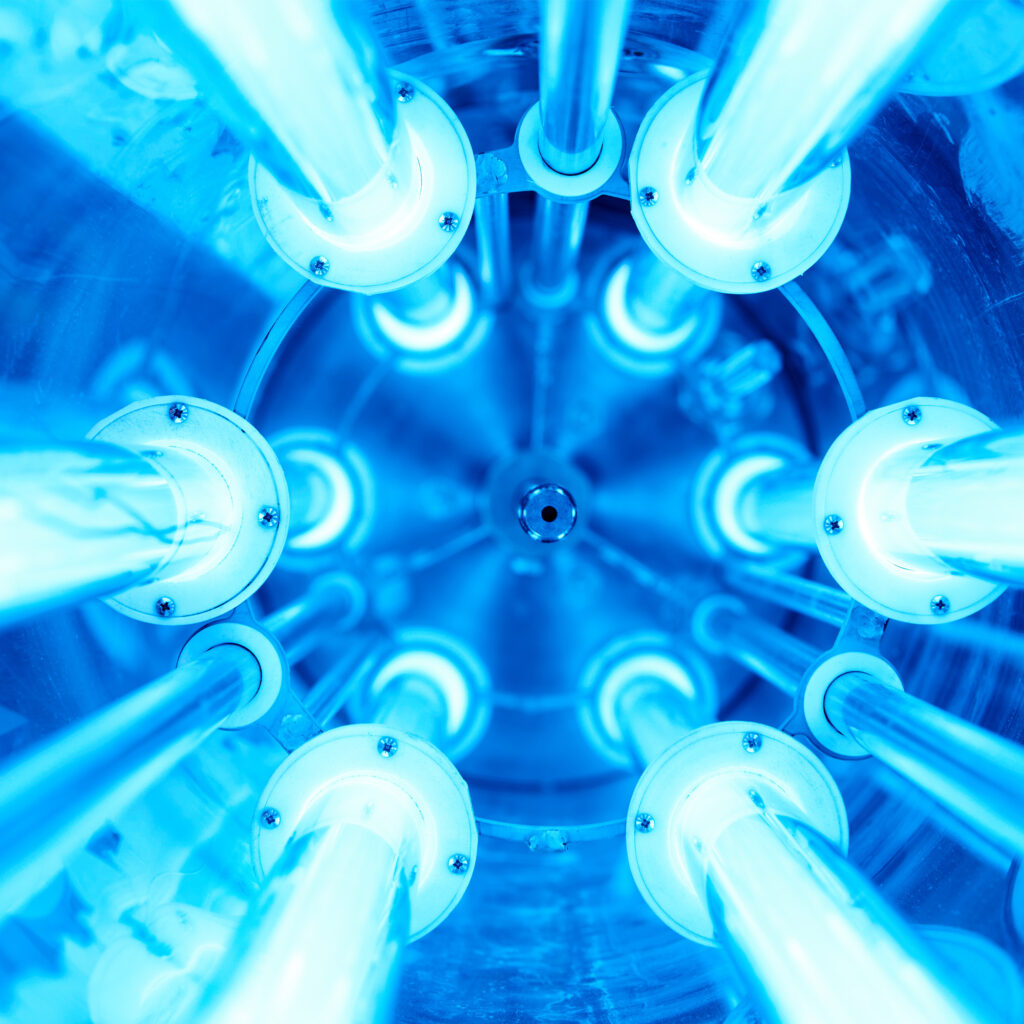

Gurtler’s innovative, patented, EPA registered Vis•Tex Tunnel UV System utilizes the latest UV technology to capture and treat tunnel press water, reducing the need for fresh water and energy while improving linen quality and reducing rewash. UV technology combined with advanced oxidation technology provides extraordinary microbial decontamination, assuring hygienically clean textiles.

Vis•Tex Tunnel UV System benefits:

- UV plus advanced oxidation technology provides microbial decontamination, assuring hygienically clean textiles.

- Powerful oxidizers deliver bright, white textiles, and provide excellent stain removal, reducing rewash.

- Water and energy savings from enhanced reuse water quality and production efficiencies.

Water Recycling

Gurtler has been a pioneer in after-market adaptations to tunnel washer systems to increase water reuse capabilities. Gurtler’s Vis•Tex Water/Energy Saver System is exclusively designed for tunnel systems. This add-on hardware system is designed for older models of tunnel washers allowing the system to adapt modern proven techniques which increase water recycling and energy capture. Users of this technology can decrease water usage by 50% while also saving up to 40% in energy usage.

Loading Factors

Wash machine loading is the number one area that must be controlled to conserve resources. Under-loading can waste labor, water, energy and chemicals, impacting the environment unnecessarily. Increasing loading factors by 5-10% can have an immediate impact in the reduction of resources. Slight increases in chemistry and in wash times can offset increased loading factors which can reduce water and energy usage.

Rinsing Efficiency

Our technicians closely monitor the rinsing operation in the laundry to make sure that excess water is not called for. Low alkaline washing technology can be utilized to reduce rinsing requirements. Use of oxygen bleaches can also conserve water with the use of combined wash and bleach operations which require less water than separate wash and bleach operations that are needed with chlorine bleaching.