Vis•Tex Central System

The Gurtler Vis•Tex Central System is a uniquely engineered liquid product injection system designed to serve your entire wash aisle, up to 10 conventional washers or washer extractors, with up to 10 different liquid products.

- Fast: High speed injection reduces wait times and improves production efficiency.

- Reliable: Metering system has no moving parts for maintenance-free performance.

- Accurate: Unique patent-pending inductive meter technology assures the right amount of product every time.

This compact, space-saving design provides maximum flexibility for chemical delivery. Gurtler’s innovative measuring and calibration technology assures accurate, precise and reliable chemical injection, every time. This Gurtler engineered system is extremely flexible, featuring two sizes: Model 1500 designed for larger washers and Model 750 for smaller washers. Units can be linked together, and all data can be merged and available for comprehensive production reporting. The Vis•Tex Central System utilizes Gurtler’s proven Vis•Tex Data Center software. The software will record and store production data, measure productivity, washer turnaround time, washer formulas, chemical usage and more. Plus, the system is compatible with the Gurtler Vis•Tex Tunnel System software, so a complete washroom productivity analysis can be obtained, and displayed on managements’ desktop computers, tablets and mobile devices. Gurtler’s Vis•Tex Central System reflects Gurtler’s commitment to our industry. Gurtler and our Technical Specialists understand what your operation needs to operate at highest efficiency. Working together, our advanced chemicals and dispensing systems incorporate all the features that will make that a reality.

Pump Module features

The Pump Module is the fastest in the market based on a comparative field study. Plus Dual-System Redundancy reduces hold time and increases productivity. Major benefits include the space-saving design; ease of installation; extremely durable pumps; accurate measuring technology and more. Two sizes available, Model 1500 for larger washers and Model 750 for smaller washers.

Specifications

- Number of Pumps: One delivery pump

- Type of Pump: Bolted, air operated double diaphragm

- Chemical resistant polypropylene/Teflon diaphragm: all wetted parts chemically resistant

-

Space Requirement:

1500: 30″ L x 34″ W x 75″ H

750: 44″ L x 24″ W x 80″ H (can be wall mounted) -

Construction:

1500: 304 stainless steel, schedule 80 chemically resistant PVC, fiberglass control enclosure

750: Stand is 304 stainless steel, schedule 80 chemically resistant PVC, fiberglass control enclosure -

Construction:

1500: 304 stainless steel, schedule 80 chemically resistant PVC, fiberglass control enclosure

750: Stand is 304 stainless steel, schedule 80 chemically resistant PVC, fiberglass control enclosure -

Construction:

1500: 304 stainless steel, schedule 80 chemically resistant PVC, fiberglass control enclosure

750: Stand is 304 stainless steel, schedule 80 chemically resistant PVC, fiberglass control enclosure -

Construction:

1500: 304 stainless steel, schedule 80 chemically resistant PVC, fiberglass control enclosure

750: Stand is 304 stainless steel, schedule 80 chemically resistant PVC, fiberglass control enclosure - Voltage: 110v

-

Air Requirements:

1500: 6-12 cfm @ 60-80 psi

750: 3-5 cfm @ 60-80 psi -

Air/Chemical Supply Lines:

1500: All lines routed to central trunk in rear of system

750: All lines routed to central from bottom of system - Hot, cold or tempered water @ 8 GPM

-

Flow Rate:

1500: 5-8 GPM

750: 2-3.5 GPM

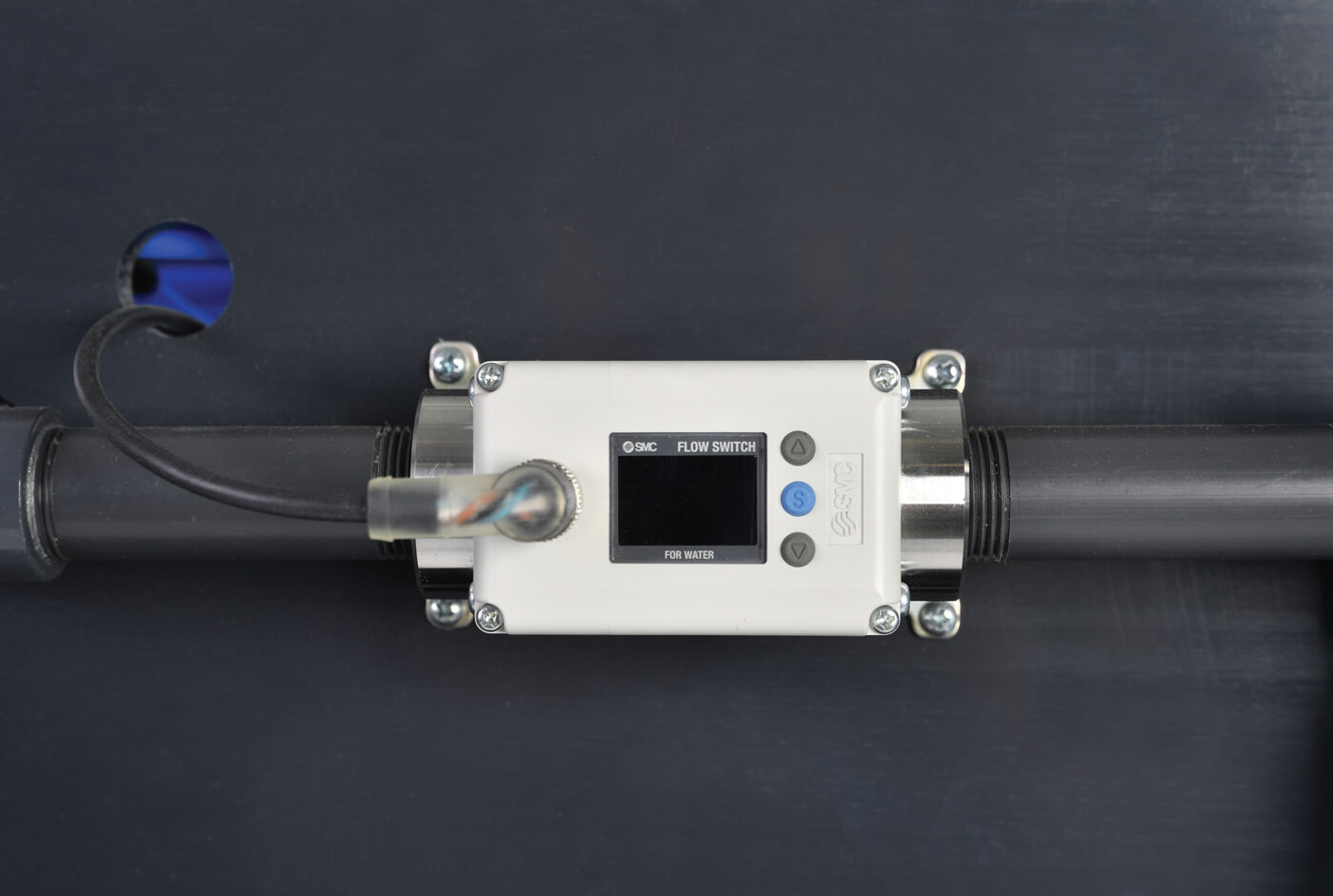

unmatched flow-metering technology

The Vis•Tex Central utilizes unmatched flow-metering technology. Gurtler’s unique meter has no moving parts and measures chemical injections based on the conductivity of each product; delivering accurate injections, real time alarms, and the fastest injection times. Assures that every chemical injection delivers the right amount of chemical, at the right time, every time!

Specifications

- Chemicals are flushed after every measurement

- Alarms for No Product, No Flush Water, Low Air Pressure and more

- Valve Type: Air-operated, diaphragm

- Valve Construction: Chemically resistant polypropylene/Teflon

- Voltage: Low: 24v.

- Calibration tube for verifying accuracy

- Programmable injection priority

- Washer hold capability

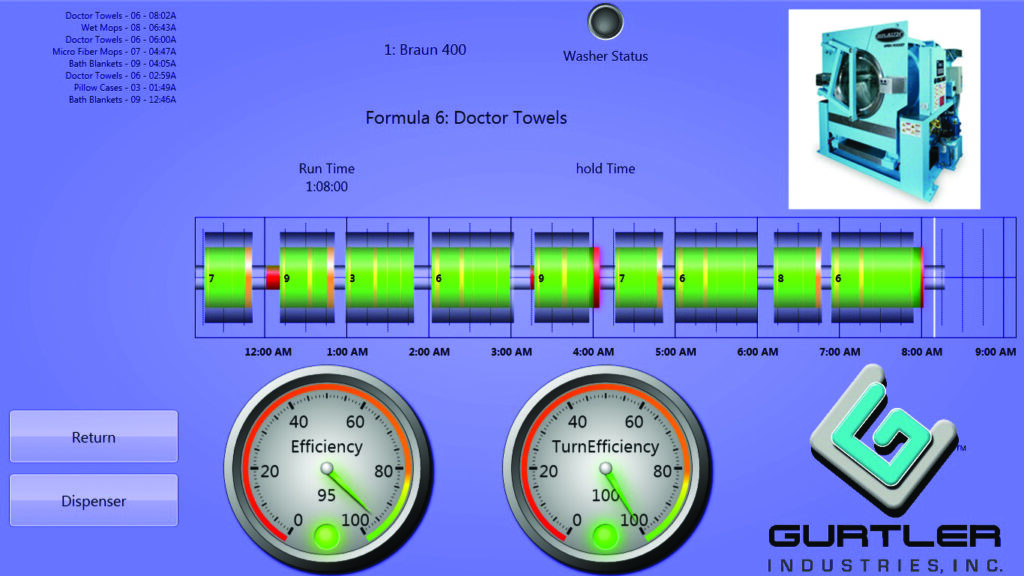

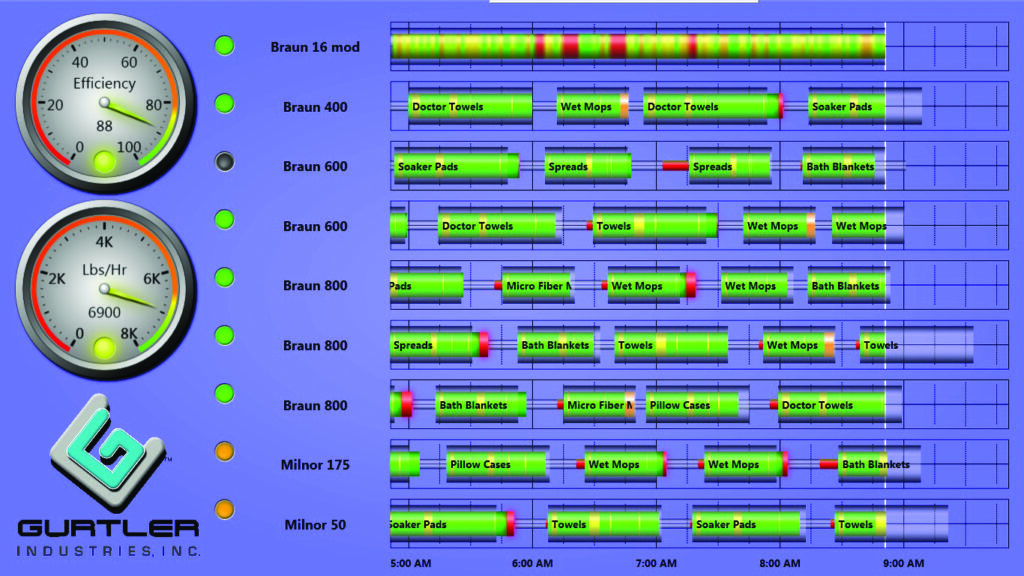

Exceptional and customizable reporting package

All your production metrics. The Data Center provides a comprehensive data management capability: Complete wash floor overview; real-time monitoring; customizable goal tracking dashboard; efficiency monitors and trend charts; fully customizable production reports, and more.

Specifications

- Remote web access and control

- Alarms for No Product, No Flush Water, Low Air Pressure and more

- Network to any computer

- Computer: Fanless industrial PC

- Monitor: 23″ touch screen